The Evolution of E-Waste Management: From RFPs to Dynamic Platforms

Insights from the Recycle Global Exchange (RGX) platform

Introduction

E-waste management is undergoing a transformation. In the United States, we are seeing a shift from traditional models to digital platform-based solutions. Historically, companies seeking to dispose of electronic waste issued Requests for Proposals (RFPs) and then selected one, two, or perhaps three vendors to manage their unwanted material streams.1 This approach often involved a lengthy process of evaluating proposals, negotiating contracts, and establishing long-term partnerships with one or more recyclers. While effective in its time, this method often lacked flexibility and efficiency in matching specific materials with specialized recyclers.

Today, platforms transform e-waste management by offering a dynamic, job-by-job mechanism for addressing reverse material flows. These platforms serve as centralized hubs where hundreds of selected e-waste recyclers can connect directly with businesses. Instead of relying on fixed service contracts, companies who join the platform can post specific e-waste jobs, allowing recyclers to bid on them.

This model brings several key advantages. Platforms can match materials with IT Asset Disposition (ITAD) companies that specialize in safely and responsibly disposing of obsolete or unwanted IT equipment, ensuring data security, regulatory compliance, and environmental management. By connecting businesses with local ITADs and other recyclers, platforms minimize transportation costs and reduce carbon footprints. Automated processes eliminate administrative overhead and provide real-time tracking, compliance reporting, and certificates of destruction.

Why the Industry is Shifting

Several factors are driving the shift toward platform models. Traditional methods often resulted in inefficiencies such as transporting waste much further than is necessary or sending recyclable materials to landfills.2 Platforms promote local recycling and adherence to environmental standards, fostering a circular economy. Technological advancements have played a role. Innovations like digital product passports (DPPs) and AI enable platforms to optimize tracking, logistics, and ensure better decision-making for manufacturers and recyclers.

Overall pressure for cost savings and better environmental outcomes has also played a role. Competitive bidding per job among recyclers reduces costs for businesses while increasing returns on recyclable materials. Likewise, platforms simplify adherence to environmental laws and industry standards by providing centralized compliance records and certified vendor options. Platforms are also better at handling the long-tail problem, as will be discussed below.

Recycle Global Exchange (RGX)

Recycle Global Exchange (RGX) illustrates the emergence of platforms in managing end-of-life electronic material streams, showcasing how digital innovation can transform e-waste management. RGX is a digital marketplace based in Colorado, that specializes in business e-waste and IT asset disposal.3 Founded in 2019, RGX connects businesses directly with local, certified vendors to dispose of electronic waste responsibly and efficiently. This platform is designed to reduce carbon footprints while increasing ROI through competitive bidding and resource management. As a neutral, automated platform, RGX directly connects businesses with certified local recyclers through a competitive bidding process. This eliminates the need for intermediaries, reduces administrative overhead, and ensures efficient handling of e-waste.

One of RGX's key strengths lies in its ability to match supply with localized recycling efforts. By matching customers with recyclers within proximity—often within 60 miles—RGX significantly reduces transportation costs and associated carbon emissions. This localized approach not only minimizes environmental impact but also supports smaller, local recyclers, fostering economic diversity and sustainability. The platform further enhances efficiency by automating job postings, bidding, and compliance tracking, enabling businesses to manage the entire e-waste process seamlessly.

RGX also prioritizes transparency and accountability. Customers can access detailed job records, including Certificates of Destruction (CODs), through a centralized database. This ensures compliance with environmental regulations while simplifying audits. The competitive bidding process ensures fair market pricing for customers while providing vendors with access to new business opportunities. The platform also automates financial transactions and provides centralized compliance records, making audits easier for businesses. Additionally, RGX tracks carbon emissions associated with each project to enhance transparency and environmental impact.

RGX operates a pilot program that allows enterprise clients to experience the benefits of RGX's digital marketplace for material disposition.4 It involves posting a series of "jobs" to demonstrate the platform's functionality, geographic reach, and pricing. RGX suggests a pilot involving at least three jobs consisting of 3-5 pallets of materials, diverse in location and material types, to demonstrate the platform's ease of use.

The five key steps of the RGX pilot include:

Onboarding: The customer works with an RGX Onboarding Specialist to set goals, timelines, and pilot job details, while also receiving platform training and job recommendations.

Post Job: The customer selects e-waste materials for disposal and uses the RGX platform to create job listings with details like quantity, condition, and pickup location.

Bidding Process: Service providers bid on posted jobs through RGX, and the customer selects the best provider based on price, certifications, and proximity.

Service Provider Selection & Logistics: Once a service provider is chosen, the RGX platform streamlines logistics by scheduling pickups or drop-offs and managing specific handling requirements.

Review Results: After job completion, the customer meets with RGX to evaluate cost savings, efficiency, and potential for full-scale implementation. RGX recommends submitting and completing at least three jobs to fully evaluate the platform.

The initiative is particularly valuable for companies with multiple locations and high volumes of electronic waste. By participating, enterprises can evaluate how the platform connects them with local, certified recyclers through a competitive bidding system, reducing transportation costs, emissions, and overall environmental impact. Additionally, the pilot provides a chance to test the platform’s features, such as tracking carbon emissions, accessing certificates of destruction, and ensuring compliance with recycling standards. By focusing on cost efficiency and environmental responsibility, RGX’s pilot program empowers enterprises to adopt a circular economy approach while optimizing their waste management strategies.

Addressing the Long-tail program

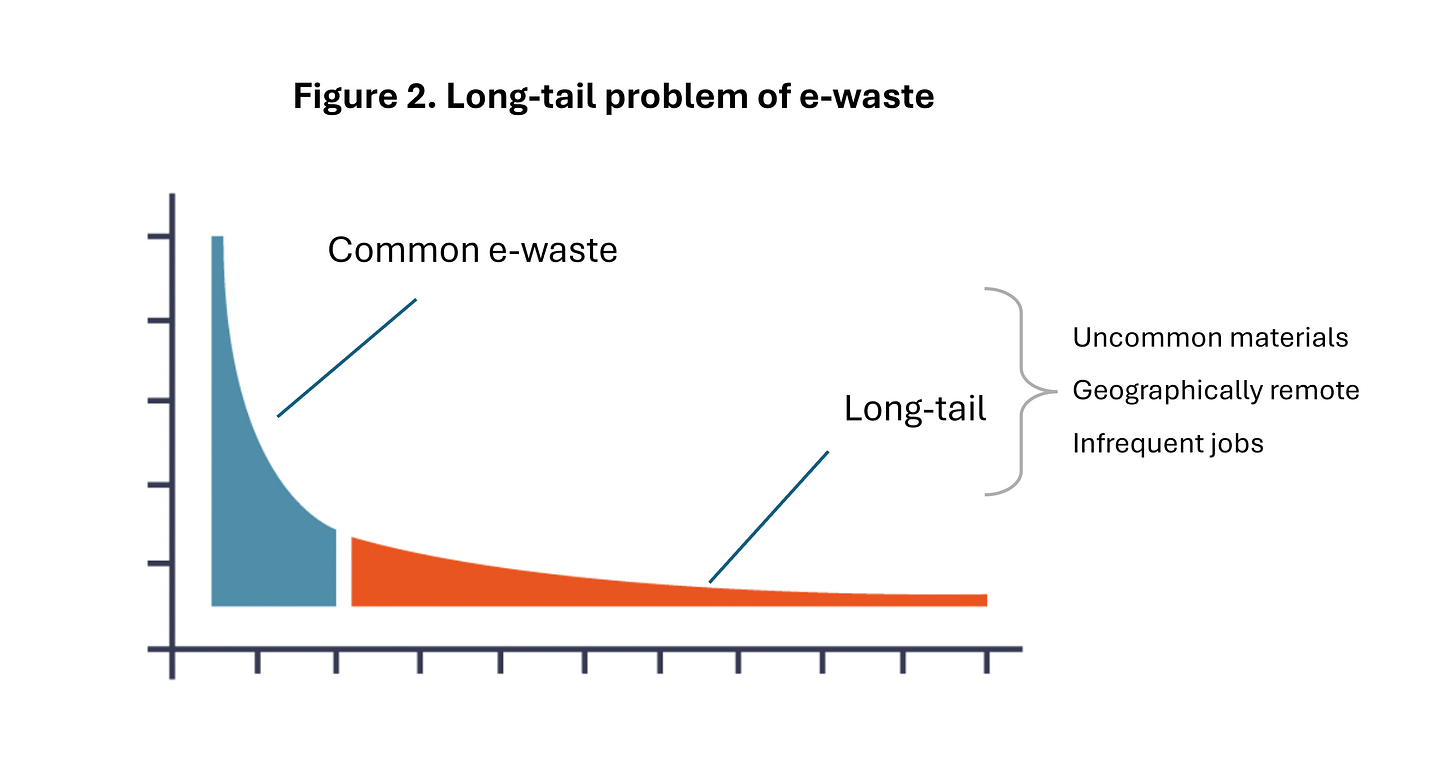

The long tail problem has been applied in retail. It illustrates the challenge of selling a large number of unique items in relatively small quantities usually in conjunction with selling fewer popular items in large quantities.5 The concept can also be applied to the circular economy. Consider the issue of managing the reverse flow of electronic waste, where a few common items are recycled in large quantities while many unique or less frequent items are processed in much smaller volumes. While some materials, such as iron and aluminum, are abundant and easier to recover in bulk, others—like rare earth elements used in smaller electronic components—appear less frequently and require specialized processes for extraction. This disparity reflects the "long tail" of material flows, where high-demand or common materials dominate the "head," while rare or niche materials form the "tail" of the distribution.

In addition to the mix of materials, the long tail challenge can also have a geographic and a time dimension. An enterprise will have sites that contain waste materials, such as factories, warehouses, or return centers that handle large volumes of widely used electronics like laptops. However, remote locations or infrequent jobs may generate smaller quantities of niche items. Managing these dispersed material flows requires efficient reverse logistics systems to ensure that even small-scale or infrequent returns are collected and processed sustainably.

Platforms like Global Recycle Exchange (RGX) are uniquely positioned to tackle the "long tail problem" in e-waste management. Traditional methods, such as issuing RFPs or relying on a limited pool of vendors, often fail to address these niche requirements effectively. In contrast, platforms with extensive ecosystems of recyclers provide a large mix of vendors that can handle a diverse mix of waste streams that fall outside common disposal needs, such as rare industrial electronics or a batch of generators that require different handling expertise.

Platforms excel in addressing the long tail problem due to their expansive network and advanced matching capabilities. Its diverse ecosystem connects hundreds of recycling companies, each with unique specializations, ensuring even rare waste streams can be matched with suitable recyclers. Dynamic matching algorithms analyze specific waste stream requirements—such as material type, regulatory constraints, and geographic location—to identify the best-suited recyclers quickly. Furthermore, RGX optimizes geographic logistics for specialized handling by locating recyclers across broader regions while minimizing transportation costs and environmental impact. The platform also provides real-time market access, enabling companies to post their needs and receive immediate bids from qualified vendors without lengthy RFP processes. This reduces downtime and facilitates timely disposal. Platforms like RGX play a pivotal role in ensuring these niche waste streams are managed efficiently and sustainably.

Conclusion

The move toward platform-based e-waste management illustrates how the circular economy is incentivizing shifts in business models. By efficiently matching waste streams with specialized recyclers, platforms ensure that valuable materials are recovered and reused rather than discarded. This reduces resource extraction, minimizes environmental impact, and extends the lifecycle of electronic products.

Moreover, the dynamic nature of these platforms fosters innovation within the recycling industry. Recyclers are incentivized to improve their processes and expand their capabilities to remain competitive in an open marketplace. This drives technological advancements that further enhance sustainability. By leveraging advanced logistics systems and digital technologies, platforms offer the potential to ensure that all types of e-waste are effectively recycled, contributing to resource efficiency and environmental sustainability.

The transition from RFP-driven e-waste management to platform-based models represents a pivotal shift in how businesses handle electronic waste. Platforms like RGX are not only streamlining operations but also contributing significantly to environmental sustainability and the circular economy. As these systems gain traction globally, they are likely to become the standard for e-waste management—offering a smarter, greener future for businesses and the planet alike.

Footnotes

Insightful as ever Peter! I wasn't aware of RGX. Very cool. Hope to see you at Circularity 25!