Platforms Built for Complex B2B Negotiations

The Case of Cling Systems EV Battery Marketplace

Introduction

In the evolving landscape of eCommerce, standardized SaaS solutions have made it easier for companies to establish 1 party eCommerce, dropship, and 3 party marketplaces contributing to the over $6 trillion in online sales globally.1 However, these systems often fall short when applied to complex B2B negotiations, such as those involving over-stock electric vehicle (EV) batteries. These transactions have an array of variables like battery chemistry, logistics, and regulatory compliance, necessitating specialized within platform negotiations.

Cling Systems, a Swedish startup founded in 2020, has developed a B2B marketplace platform to address these challenges, promoting circularity in the battery lifecycle.2 This article explores how innovations by Cling Systems has contributed to enhancing complex negotiations by providing a centralized hub that organizes, structures, and selectively shares critical information, thereby improving the efficiency of EV battery transactions and supporting a sustainable battery ecosystem.

Why Marketplace Software Solutions Fall Short for Complex B2B Deals

In the early days of eCommerce, companies developed their own software stacks to manage transactions, which required significant resources and technical expertise. These custom-built systems were complex, expensive, and often lacked scalability. Over time, the emergence of Software-as-a-Service (SaaS) solutions like Shopify, Mirakl, Logicbroker, and Marketplacer transformed the eCommerce landscape by offering standardized marketplace software platforms. They are particularly effective for consumer goods and straightforward B2B transactions where pricing, specifications, and terms are largely uniform, and products can be organized into catalogues.

However, these software systems do not work well for B2B transactions that require complex negotiations. Electric vehicle (EV) battery transactions are a case in point. The sale of EV batteries involves complex variables that go well beyond fixed-price models. Key factors such as battery chemistry, remaining capacity, transportation logistics (including hazardous material handling), and commercial competitive concerns make these transactions highly intricate and sensitive.

Sellers of EV batteries may be reluctant to disclose detailed information about their sales and inventory for several reasons. First, such information is highly sensitive from a competitive standpoint. Publicly revealing battery sales or inventory levels could expose an OEM's market position, such as whether it has overpurchased batteries or is failing to meet production targets. This could weaken their negotiating power with suppliers or partners and provide competitors with valuable strategic insights. Additionally, sharing detailed data might inadvertently reveal proprietary strategies, such as the adoption of specific battery chemistries (e.g., LFP vs. high-nickel batteries), which competitors could exploit.

There are also financial, supply chain, and strategic considerations at play. Disclosing sales data could lead to financial risks, such as a decline in investor confidence and stock prices if inefficiencies are highlighted. It could also harm consumer confidence by creating negative perceptions about the company’s ability to meet production targets. Furthermore, revealing overreliance on specific suppliers could expose vulnerabilities in the supply chain, attract regulatory scrutiny, or raise concerns about quality control issues. Finally, maintaining secrecy helps OEMs preserve leverage in negotiations and protect ongoing strategic initiatives, such as in-house battery production or partnerships with suppliers. Overall, these factors contribute to a reluctance to make such information public, as it could negatively impact business operations and market standing.

Cling Systems Platform

Cling Systems is an example of a company building solutions to address the unique requirements associated with complex high value products. Cling Systems is a Swedish startup that has developed a B2B marketplace platform that can address the challenges associated with complexity of EV battery transactions. Founded in 2020 and headquartered in Stockholm, the company focuses on promoting circularity in the battery lifecycle by facilitating the resale, reuse, recycling, and repurposing of lithium-ion batteries. Their mission is to close the loop on battery usage, ensuring environmental sustainability and the special challenges posed in facilitating deals between buyers and sellers of large battery systems.3

The Cling platform connects supply and demand within the battery ecosystem, enabling organizations to efficiently manage discovery, matching, price negotiations, paperwork management, and logistics. The focus of the platform is on larger over-stock of batteries (“idle batteries”) from battery producers, OEMs, which includes cells, modules, and complete packs. Parties that participate on the platform often list as much as 10-50 MWh at a time, which equals 200-1,000 EV packs (á 50kwh).

By integrating comprehensive data management tools, the platform provides precise insights into battery conditions, technical specifications, as well as quantities, delivery dates and other essential parameters in closing a deal. This structured approach helps maximize both environmental and commercial benefits while simplifying compliance with strict regulations that cover large batteries.

Cling Systems also emphasizes user accessibility through an intuitive interface that structures complex information in a digital environment that gives each party control over the information they share during negotiations. With successful transactions in over 20 countries in North America, Europe and Asia, the company has aims to build a platform that can serve buyers and sellers throughout the world.

The Deal Room

Initially, the team at Cling Systems focused on building liquidity by attempting to onboard as many buyers and sellers as possible However, through the process of working with companies, the team found that the total number of buyers and sellers was not the real constraint on liquidity. It was the complexity of the transactions. This insight led to the creation of the Deal Room.

The Deal Room is a specialized feature within Cling Systems’ platform designed to streamline the process of arriving at a deal between battery buyers and sellers. It acts as a single source of truth, guiding the parties through every step of the transaction process. It is a negotiation tool that includes functionalities such as discrepancy flagging, which allows for the early identification of issues to reduce liabilities and claims. Additionally, it provides a means to structure technical and pricing offers in ways that that help the parties compare alternatives and align more quickly on an agreement. The Deal Room also prioritizes data privacy, providing granular control over what information is shared to ensure confidentiality and security during negotiations. By consolidating this information in one place, the Deal Room eliminates scattered communications and ensures that both parties work from the same data, reducing confusion and delays.

The platform also helps detect discrepancies early in the process by automatically flagging mismatches in battery condition assessments, pricing expectations, or compliance documentation. This proactive approach minimizes post-deal disputes and mitigates liability risks. Additionally, the Deal Room offers collaborative tools such as real-time commenting, version-controlled document sharing, and automated reminders for pending actions. These features streamline internal approval processes and reduce negotiation timelines by 30–50%, based on Cling Systems' pilot projects.

The Deal Room consolidates essential data such as battery chemistry, remaining capacity, hazardous material handling protocols, and is designed to adherence to future regulations like the EU Battery Passport. This structured approach ensures that buyers and sellers have access to accurate and relevant information, facilitating smoother negotiations These features minimize manual research efforts and enhance decision-making efficiency.

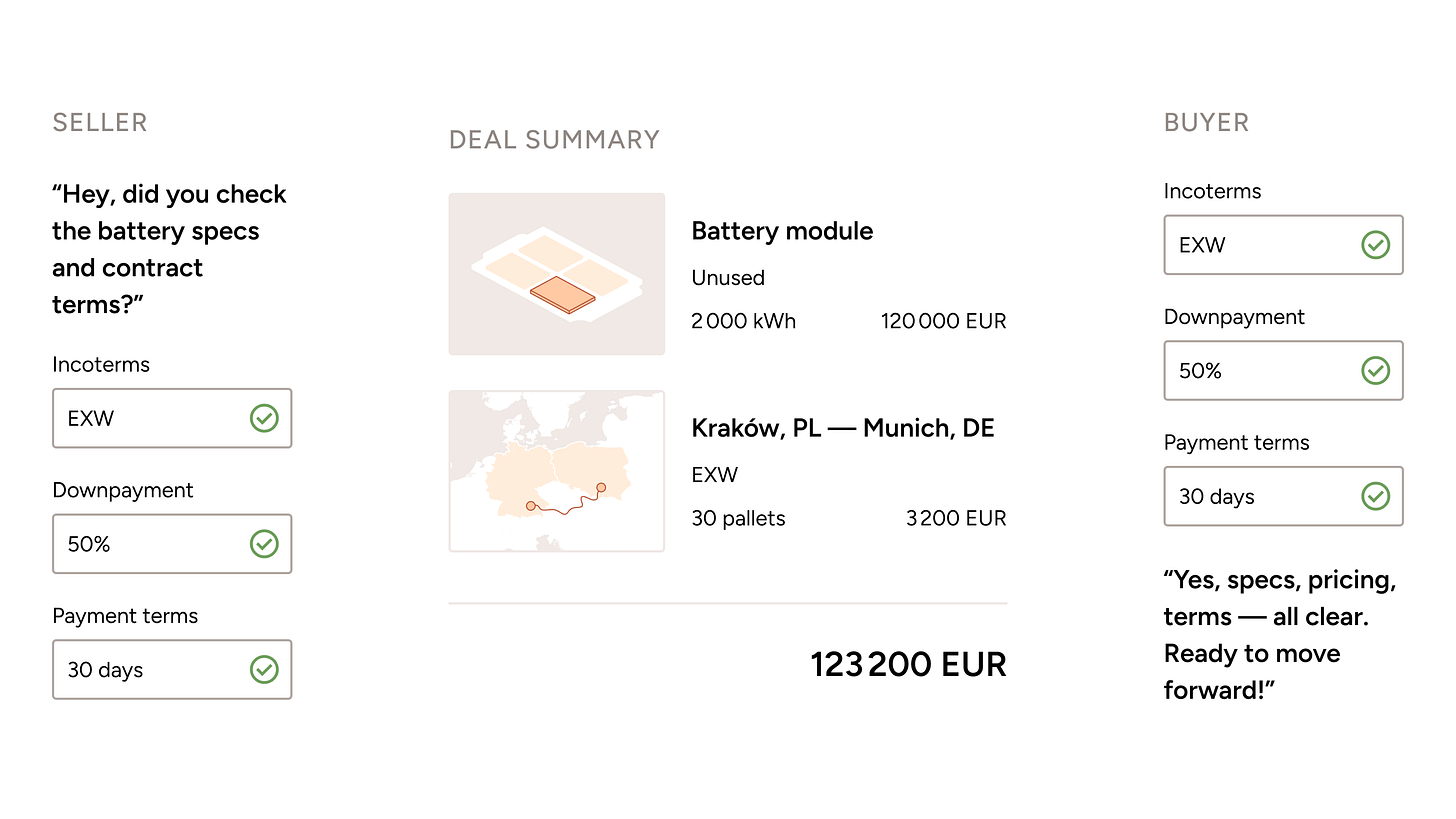

A unique aspect of Cling Systems' platform is its ability to allow parties to selectively reveal information during negotiations. Sellers and buyers can withhold sensitive data until they are ready to share it, ensuring that negotiations progress at a comfortable pace while maintaining strategic control (see Figure 1). This feature builds trust and reduces risks associated with premature disclosure of proprietary or sensitive details.

Figure 1: Selective Information Sharing

Furthermore, the Deal Room structures transaction-related information in a way that directly supports negotiation outcomes. By organizing technical specifications, logistics costs, and compliance documentation into an accessible format, it eliminates scattered communications and ensures both parties work from the same dataset. This streamlined process by enabling private information exchange and the ability to quickly test different offers, which reduces delays and confusion while enhancing the bargaining process (See Figure 2). By digitizing traditionally manual processes and providing structured workflows, the Deal Room reduces average negotiation times from weeks to days while improving auditability—an essential feature for an industry that handles hazardous materials under strict regulatory requirements.

Figure 2: Cling System Deal Room

In addition to addressing logistical challenges, Cling Systems collaborates with selected partners for transport, testing, and recycling services. These partnerships further mitigate risks and improve reliability in fulfilling deals. By combining centralized data management with selective information sharing and robust structuring tools, Cling Systems' Deal Room significantly improves the efficiency of EV battery transactions while supporting circularity in the battery ecosystem.

Other Features of the Platform

Cling Systems' platform offers a range of features beyond the Deal Room that enhance deal-making and address the complexities of trading and transporting lithium batteries. One feature is document automation for logistics, which simplifies the preparation, storage, and distribution of the extensive documentation required for transporting lithium batteries. This service addresses the unique challenges of transporting batteries and extensive regulatory compliance issues. By automating these processes, Cling Systems reduces lead times and minimizes errors, ensuring compliance with strict regulations.

The platform is designed to become a complete Circular Asset Management (CAM) system, which tracks the lifecycle of batteries to provide insights into past trades, second-life applications, and recycling proportions. This will ensure traceability and compliance while optimizing strategies for reuse and recycling to maximize battery value retention. The Related Batteries Tool further supports decision-making by visualizing connections between different batteries, helping users identify compatible modules or packs for repurposing or recycling. Lastly, Cling Systems offers trade finance solutions to help companies overcome cash flow challenges and scale their operations effectively.4 Together, these features streamline sourcing, trading, logistics, and compliance processes, fostering a more efficient and sustainable circular economy for lithium-ion batteries.

Conclusion

EV batteries present an example of complex transactions that are not served by conventional platform technologies. This has required new innovations as illustrated by the case of Cling Systems. The solution developed over several years of trial and error has led to the creation of deal rooms that structure private information sharing and bargaining between battery buyers and sellers. Cling Systems' Deal Room ultimately improves negotiation efficiency, reduces risks, and fosters trust between buyers and sellers in the EV battery ecosystem. Moreover, it significantly contributes to a sustainable and circular economy by promoting the efficient balancing of supply and demand for lithium-ion battery inventory.

Footnotes